- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

The VNA (Very Narrow Aisle) Racking System, also known as narrow aisle racking, is a high-density storage solution designed to maximize warehouse space. By reducing aisle widths from the standard 2.5–3.5 meters to just 1.5–1.8 meters, it frees up nearly 50% more storage area. Utilizing both horizontal and vertical space (up to 12–17 meters high), VNA racking can increase storage capacity by 40–50% compared to conventional selective systems. It supports FIFO and LIFO operations, ensuring flexibility and efficiency in inventory management. This makes VNA racking ideal for space-limited warehouses that require high-density, safe, and efficient storage, especially in industries such as logistics, food & beverage, pharmaceuticals, and cold storage.

VNA (Very Narrow Aisle) Racking is a high-density storage system designed to maximize warehouse space by minimizing aisle width. This system is particularly suitable for storing uniform goods in warehouses and factories with limited floor space but high ceilings.

Heavy-Duty Load Capacity: Supports up to 1,000 kg per pallet.

Optimized Storage Utilization: Maximizes both horizontal and vertical space, with racking heights reaching up to 17 meters. Reduces aisle width to below 2 meters, significantly increasing storage density.

One of the most preferred pallet racking systems today due to its high space efficiency and accessibility.

VNA Racking with narrow aisles optimizes storage space by up to 40%

The distance between the aisles of VNA shelves is less than 2 meters

The VNA Racking System is made from high-quality steel, with an electrostatic powder-coated finish to prevent rust and corrosion, ensuring safety for both workers and stored goods.

Main Components of VNA Racking

Additionally, based on actual warehouse conditions, our team provides customized solutions to enhance safety and long-term efficiency of the VNA Racking System.

Simple structure, suitable for use in warehouses with narrow areas

Designed to minimize aisle width while ensuring enough clearance for specialized VNA forklifts to operate efficiently.

Increases warehouse storage capacity by up to 70%, effectively doubling storage density compared to conventional racking systems.

Enhances warehouse operations and reduces warehouse management costs.

With an average lifespan of over 15 years, businesses save on repair and replacement expenses.

Manufactured with strict technical standards, using premium-grade steel.

Electrostatic powder coating ensures rust resistance, strong oxidation protection, and environmental durability.

Unlike other high-density storage systems that limit pallet access, VNA Racking still allows smooth and efficient material handling.

Designed to fully utilize vertical storage capacity, reaching up to the warehouse ceiling for maximum space optimization.

Eurorack VNA racks efficiently handle heavy loads with narrow spaces

VNA Racking is a high-density pallet storage solution designed for warehouses with limited floor space, helping to optimize storage capacity while significantly increasing pallet density. The operation process of VNA racking involves the following key steps:

Operators must use a specialized Very Narrow Aisle forklift to ensure safe and efficient pallet handling.

The forklift operator carefully positions the vehicle within the narrow aisle and maneuvers it to retrieve or store pallets as needed.

* Important Considerations:

Due to the extremely narrow aisle design, only one forklift can enter the aisle at a time.

New or inexperienced operators may face challenges in maneuvering VNA forklifts within such restricted spaces, requiring proper training and practice for smooth operations.

VNA Racking is widely used in modern warehouses due to its space optimization capabilities, but it is particularly well-suited for the following types of storage facilities:

VNA Racking are suitable for all types of warehouses with narrow areas and high storage density

With over 15 years of expertise in large-scale warehouse racking projects, Eurorack has established itself as a trusted manufacturer and installer of VNA racking systems in both domestic and international markets.

Eurorack specializes in manufacturing and installing VNA racks with narrow aisles without intermediaries

Eurorack offers outstanding advantages in VNA racking solutions, ensuring quality, efficiency, and reliability for your warehouse storage needs.

Manufactured from SPCC Grade 1 cold-rolled steel, ensuring aesthetically refined, stronger, and more durable racking systems.

High-tech and automated production lines meet European standards.

A highly experienced installation team, ensuring consistent quality and on-time project completion.

Complimentary warehouse assessment and consultation to recommend the most suitable storage solutions.

2D & 3D design simulations tailored to customer requirements.

Customization available for color, size, and technical specifications, ensuring optimal storage efficiency for different business needs.

End-to-end production and installation handled by Eurorack, reducing project lead times and ensuring seamless execution.

Trusted by Global Brands: Pepsico, Coca-Cola, Nestlé, Sanko, and more.

Need a customized VNA racking solution? Contact Eurorack today for expert consultation and support!

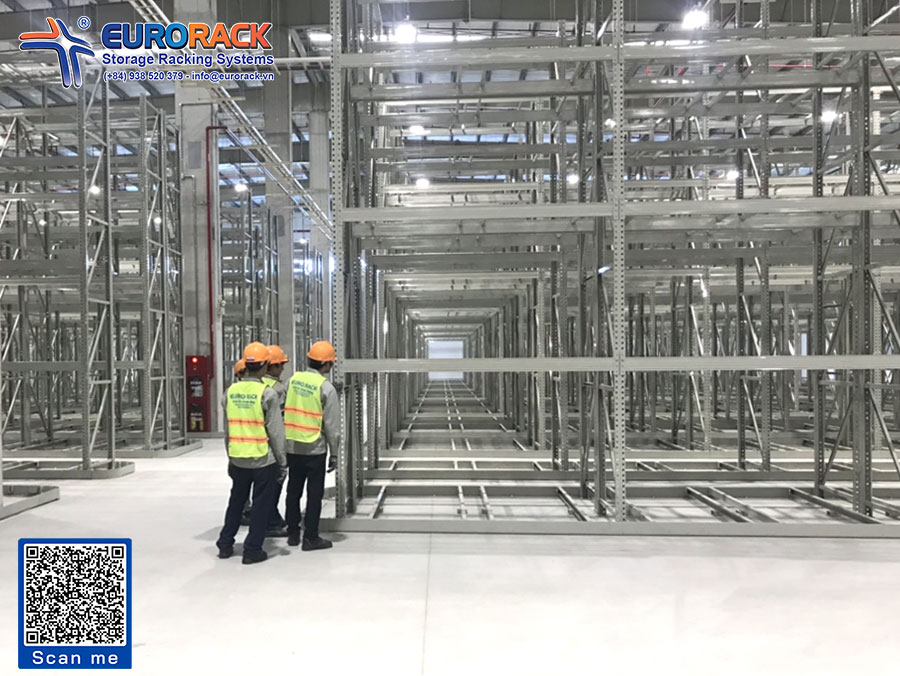

Eurorack deploys and installs high-quality VNA Racking (1)

Eurorack deploys and installs high-quality VNA Racking (2)

Eurorack deploys and installs high-quality VNA Racking (3)

Eurorack deploys and installs high-quality VNA Racking (4)

Eurorack deploys and installs high-quality VNA Racking (5)

Eurorack deploys and installs high-quality VNA Racking (6)