- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

Pallet Flow Rack, also known as roller pallet racking, is a high-density industrial storage system that utilizes gravity rollers (rulo) to facilitate pallet movement.

This racking system is widely recognized as one of the most efficient and safest warehouse storage solutions available today, ensuring high storage density and optimized material flow.

Video introducing Pallet Flow Rack - Smart storage system

Pallet Flow Rack, also known as roller pallet racking, is a high-density storage system that utilizes rollers to move pallets efficiently. With its unique design, this system minimizes forklift contact with racking structures, making it one of the safest and most space-efficient warehouse storage solutions available today.

To determine the best racking system for your warehouse, let Eurorack guide you through the key features and benefits of Pallet Flow Racking.

Learn about what is Pallet Flow Racking?

Pallet Flow Racking consists of a pallet support frame combined with gravity rollers. The system is slightly inclined, with a higher entry point and a lower exit point. This design allows pallets to move downward naturally using gravity, enabling faster and more efficient pallet retrieval.

Follows the FIFO (First In, First Out) principle, ensuring automatic stock rotation.

Pallets move smoothly along the rollers, reducing handling time and improving inventory control.

Highly effective for large-scale warehouses requiring continuous material flow.

With its automated pallet movement and inventory management efficiency, Flow Racking is a preferred choice for many businesses looking to streamline warehouse operations.

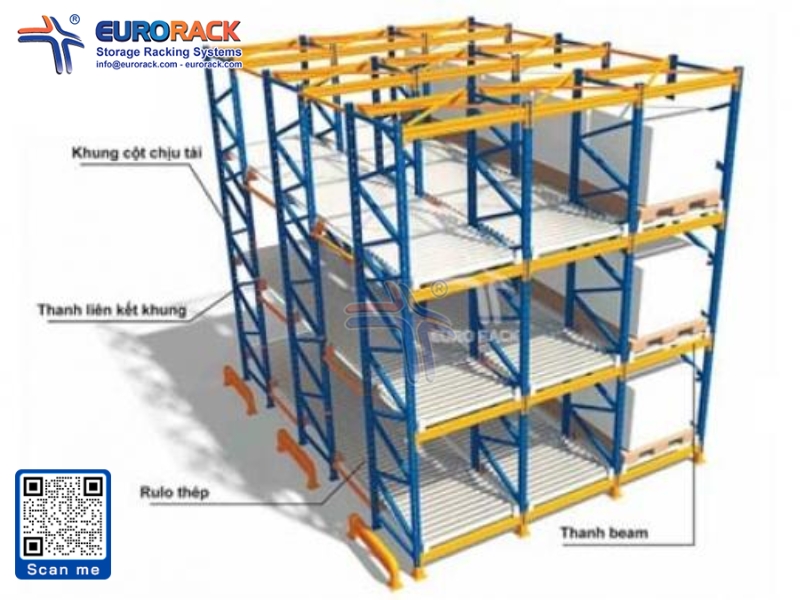

The Pallet Flow Rack System consists of five key components, ensuring high load capacity and smooth pallet movement:

Primary load-bearing structure supporting the entire racking system.

Distributes load evenly between the upright frames, enhancing stability.

Connects two upright frames and serves as the primary support for pallets.

Reinforces the beams to keep pallets securely in place.

Enables smooth pallet movement while ensuring safety and operational efficiency.

* Important Note: All components are modular and assembled using bolts and screws, allowing for flexibility in installation, easy adjustments, and reconfiguration when needed.

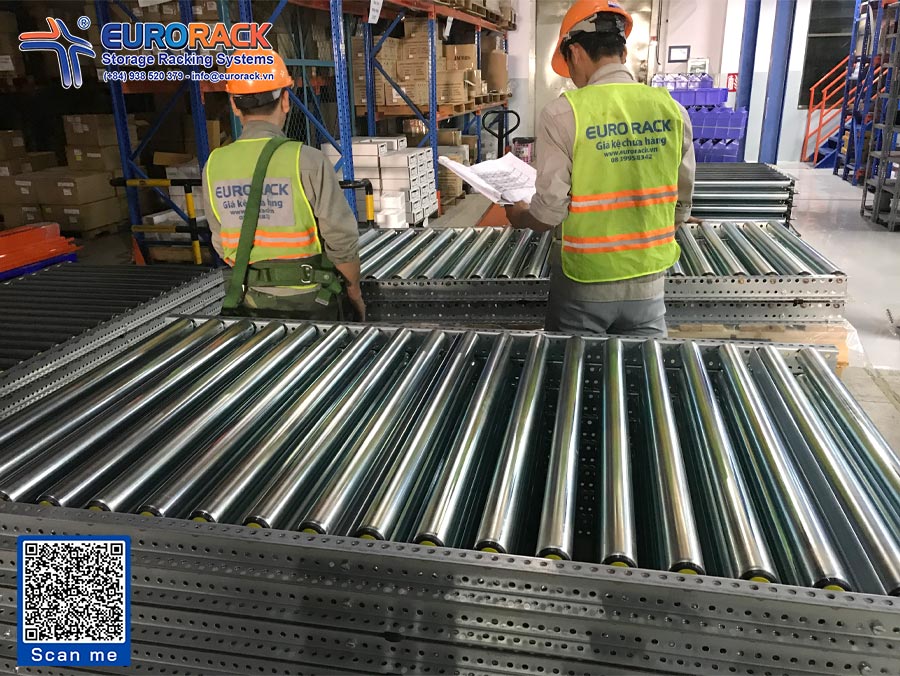

Steel roller systems are used to install Pallet Flow Racking

*Note: Pallet flow racks are most effective when used for homogeneous product storage. For warehouses with a variety of products, managers should establish a separate area to avoid confusion, mixing, and product loss.

Flow Racks are designed with a slight incline of 1 to 3 degrees, allowing pallets to slide forward using gravity towards the picking end. This reduces unloading time and streamlines warehouse operations.

Pallet Flow shelves operate based on gravity

Flow Rack Systems are an ideal solution for industries requiring high-density storage and efficient inventory turnover. They are best suited for:

As one of Vietnam’s leading manufacturers in the pallet racking industry, Eurorack is a trusted partner of major domestic and international corporations, including Nestlé, PepsiCo, Vinamilk, and more.

Eurorack is the leading Pallet Flow racking manufacturing brand in Vietnam

Looking for a reliable Flow Rack supplier?

Contact Eurorack today for a free 3D warehouse simulation, site measurement, and an accurate installation quotation!