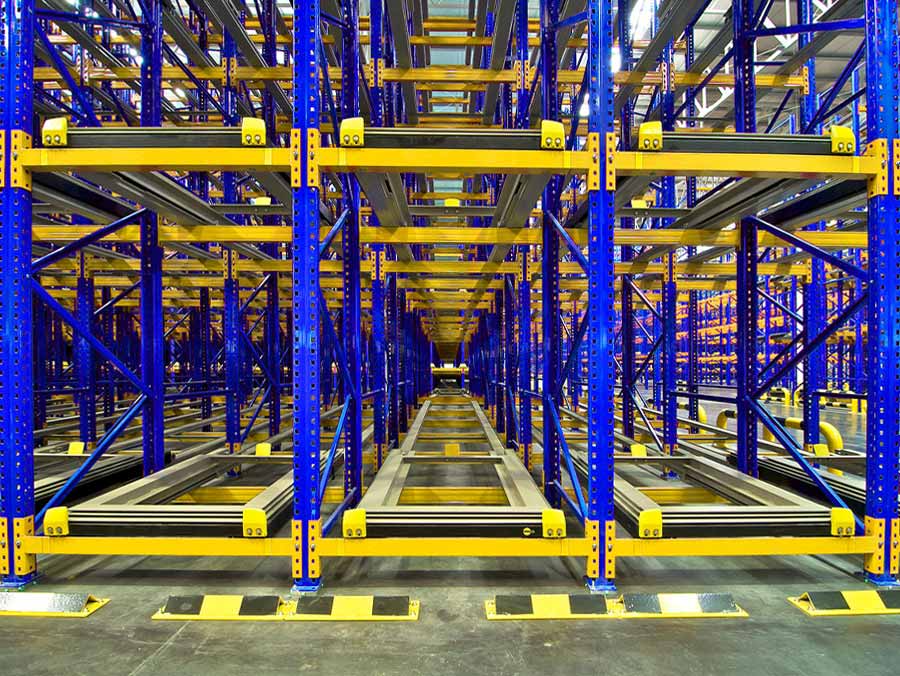

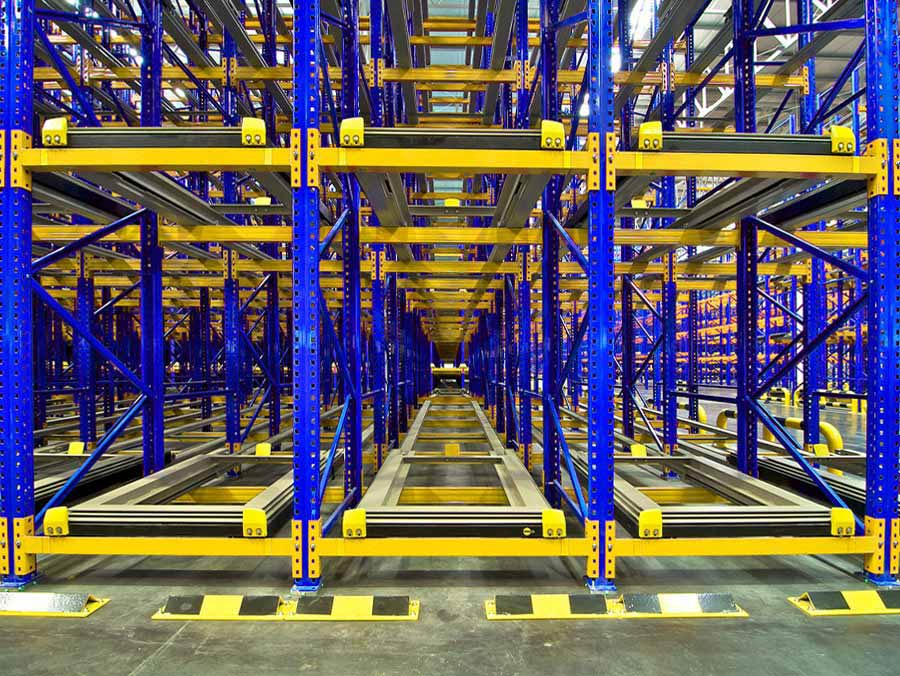

Push Back Racking is a pallet storage system that operates on an automatic load accumulation principle, helping to increase storage density without the need to expand warehouse space. Each storage lane can hold between two and six consecutive pallets, operating under the LIFO – Last In First Out mechanism, meaning the last pallet loaded is the first to be retrieved.

- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

.jpg)