- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

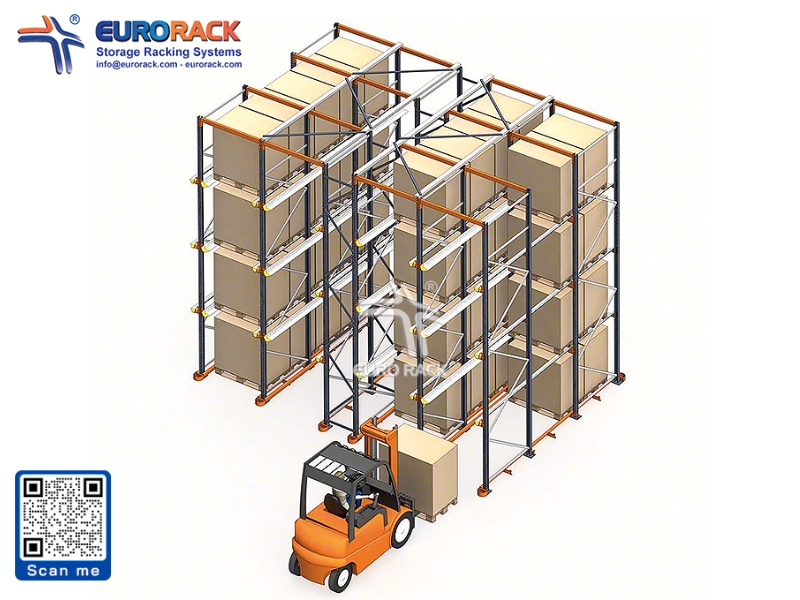

Drive-In Racking is a heavy-duty warehouse racking system widely used in high-density storage applications. Its design allows forklifts to access pallets from both ends of the racking structure, making it compatible with both FIFO (First In, First Out) and LIFO (Last In, First Out) inventory management principles across various industries.

Let's explore Drive-In pallet rack with Eurorack

Drive-In Racking is one of the most widely used heavy-duty racking systems today. Its flexible operation, supporting both LIFO (Last In, First Out) and FIFO (First In, First Out) principles, makes it an ideal choice for warehouse optimization. Understanding the features of Drive-In Racking will help you determine whether it is the optimal solution for your storage needs.

Drive-In Racking is designed for high-density storage of heavy-duty loads, eliminating unnecessary aisle space and maximizing over 70% of floor storage capacity. To load and retrieve pallets, forklifts simply drive into the rack system, positioning the forks directly under the pallets.

The racking rows are securely interconnected, with each level incorporating deep pallet rails inside the structure. This design ensures stability and makes Drive-In Racking ideal for warehouses storing homogeneous palletized goods, supporting both FIFO and LIFO inventory management systems.

Powder-coated Eurorack Drive-in Racking

The Drive-In Racking System consists of eight essential components:

Supports the entire racking structure.

Constructed with two Omega-shaped perforated upright columns for high load capacity.

Connects the upright frame to the warehouse floor.

Made from 2mm thick solid steel for enhanced stability.

Installed horizontally and vertically between upright frames.

Ensures even load distribution across the racking system.

Horizontally connects the top sections of the uprights, reinforcing the structural integrity of the entire rack system.

Holds the pallet weight and evenly distributes the load to the racking frame.

Each storage lane is fitted with two parallel pallet guide rails.

These allow for precise pallet positioning and secure storage.

Anchors the load-bearing upright to the warehouse floor, ensuring rack stability.

Prevents damage to the racking system by shielding it from forklift collisions.

The racking system fully utilizes all available warehouse dimensions, including height, width, and depth. This leads to significantly higher storage capacity compared to conventional racking systems.

By reducing storage space requirements, Drive-In Racking minimizes energy consumption for lighting and climate control systems.

With a lane-based storage system, each SKU is assigned to a dedicated storage lane.

This allows warehouses to store a variety of product types efficiently.

The high storage density, simple structure, and efficient operations make Drive-In Racking a cost-effective solution for businesses.

Designed for forklifts to access pallets from both ends of the racking row.

Supports both FIFO (First In, First Out) and LIFO (Last In, First Out) inventory methods.

Can be used in cold storage warehouses with temperatures as low as -30°C.

Each racking design configuration provides optimized storage solutions for industrial warehouse applications.

Eurorack's Drive-In warehouse rack system is strong, durable, and ideal for manufacturing material storage

For Drive-In Racking, pallet loading and unloading processes vary based on racking layout configurations:

1. Single-Entry Drive-In Racking

In this setup, one end of the racking row is positioned against a wall.

Since pallets can only be accessed from one side, this configuration follows the LIFO (Last In, First Out) inventory method.

2. Double-Entry Drive-In Racking

The racking system is installed in an open space within the warehouse or at a sufficient distance from the wall, allowing forklift access from both ends.

With two entry points, warehouse operators can load and retrieve pallets from either side, significantly improving operational efficiency.

Important Loading Guidelines

*Note: When loading goods, follow the sequence. Fill the top layer of a lane first, then the lower layers. Continuously do this until the lane is filled with pallets.

Drive-In Racking is an ideal choice for manufacturing and commercial businesses that require high-density pallet storage while optimizing warehouse space efficiency. This system is particularly suitable for:

Drive-In Pallet Racking for companies operating in the field of construction materials

Eurorack is a prestigeous and reputable brand in the manufacturing and installation of Drive-In Racking systems. The manufacturing process meets ISO 9001:2015 standards. The products comply strictly with European standards. With modern machinery imported from Europe and Japan, along with a highly skilled technical team, Eurorack can accurately and promptly meet all usage needs.

Eurorack team professionally installs Drive-in pallet racking, ensuring on-time delivery

Eurorack is a leading and trusted brand in the design, manufacturing, and installation of Drive-In Racking systems. Our production process adheres to ISO 9001:2015 standards, ensuring strict compliance with European quality regulations. The entire manufacturing line features state-of-the-art machinery imported from Europe and Japan, guaranteeing precision and durability.

As a direct manufacturer and distributor, Eurorack offers competitive pricing, making our solutions accessible to businesses of all sizes across various industries. Drive-In Racking prices range from 2,600,000 to 5,000,000 VND, depending on system specifications and warehouse requirements.

With nearly 14 years of experience in the industrial racking industry, Eurorack is a trusted partner of major corporations, including Nestlé, PepsiCo, Lotte, Yamaha, Sanko, and more.

Contact Eurorack today! Our team is ready to assist you in finding the most efficient and optimized warehouse storage and automation solutions for your business